Buy slewing bearing – What should you know?

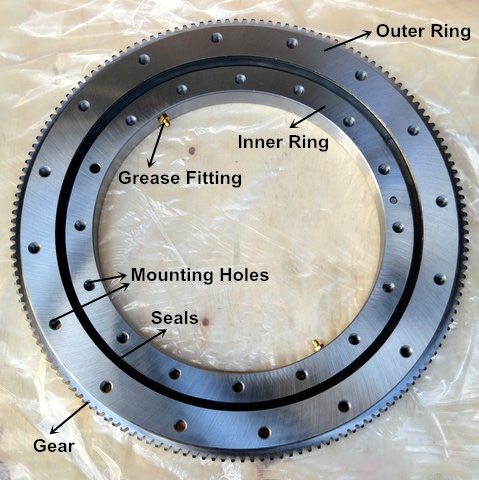

If you want to buy a slewing bearing, you need to understand this product. Firstly let's take a look at what is a slewing ring bearing composed of. The below picture shows the major components of a slewing bearing.

Inner ring and outer ring

A slewing bearing consists of an inner ring and an outer ring, and the material is generally 50Mn or 42CrMo. Each ring includes at least one precision raceway to transmit load and realize the relative rotation of the two parts of the equipment. Selective hardening of the raceway surface and a certain depth can better disperse the high stress generated during the operation of the transmission equipment.

The figure below shows the typical hardening of four-point contact ball slewing bearing and crossed roller slewing bearings. The processing method of the multi-row slewing bearing high-stress raceway is similar to the above series. At a certain position near the raceway, there will be a non-hardened area, which is called a hardness gap or "soft spot". This area can share the stress so that the performance of the rolling element will not be impaired. Only one side of each bearing ring is connected to the supporting structure. Besides, one ring may have a complete transmission structure, such as gears.

ball slewing bearing raceway hardening

roller slewing bearing raceway hardening

So when buy slewing bearing, you need to confirm with your supplier what is the material you prefer? Which type of structure do you need? So that slewing bearing manufacturers can quote you the accurate price.

Rolling elements

The precision-made rolling elements make the relative rotation and load transfer performance between the inner and outer rings better. Usually, balls or rollers are made of hard chrome alloy such as GCr15 bearing steel. The designed size of the rolling elements is the most suitable to cope with the expected stress and uniform load of the inner and outer rings and can reduce the rotation resistance to the greatest extent.

Spacer retainer

Spacers are used to separate the rolling elements, which can reduce friction and prevent slippage and seizure during the rotation of the bearing. The spacer retainer is generally made of plastic, and won't be affected by common lubricants in a general operating environment. In some cases, for ball bearings, smaller balls will be placed between the large balls taking the load instead of spacers. This can also be called "separation ball", which can provide unique solutions for some special application environments.

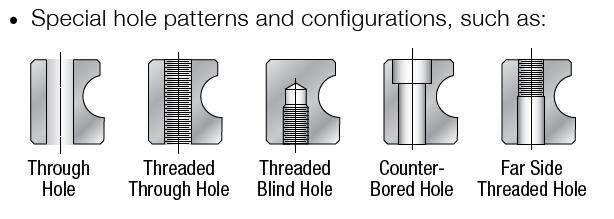

Mounting hole

The ideal mounting hole pattern for the two rings of the fixed turntable bearing should be a through-hole evenly distributed along one circle. However, in fact, equipment designers cannot guarantee enough space. In order to facilitate installation and maintenance, it may be necessary to use threaded holes or even special bolts on one or two bearing rings for fixing.

Sealing

Each slewing bearing is equipped with a seal to prevent the loss of lubricant and protect the bearing from contamination by dust and particles. The seal is made of elastic material and does not conflict with most common mineral oil lubricants and lithium-based or calcium-based thickener greases.

Filling plug

The rolling elements of the slewing bearing can be inserted through the radial drilling hole on the ring that without gear, and then block the hole. The plug is mechanically locked with a positioning pin to ensure it is in the proper position and orientation. However, some customized slewing bearings are split type, the rolling elements can be loaded into the raceway through the split ring.

Note: Removing the ball hole plug will invalidate the warranty clause.

Gear teeth

The inner ring or outer ring of the turntable bearing can be processed with the gear. Usually can provide full-tooth high gears or involute gears with a pressure angle of 20 degrees. The backlash meets the relevant regulations.

Of course, according to customer needs, we can also adjust the basic tooth profile, pressure angle, and accuracy, and provide customized products. To facilitate assembly, the highest point of the gear's radial runout is marked. This can also be changed if requested by the customer.

Grease nipple

At least one grease nipple is located on a certain bearing ring, through which the raceway and internal structure can be lubricated periodically. For bearings with gears, it is often located on a toothless bearing ring, and the number of grease nipples tends to increase as the diameter of the bearing increases.

After understanding the basic characteristics of slewing bearing, you may need to know how to select slewing bearings.