Cross roller bearing design – Detailed analysis of each component

In recent years crossed roller bearings become more and more popular, because of its high rotation accuracy and ability to take combined loads. Why does a cross roller ring have these features? We need to understand the cross roller bearing design first.

Cross roller bearing design - Components

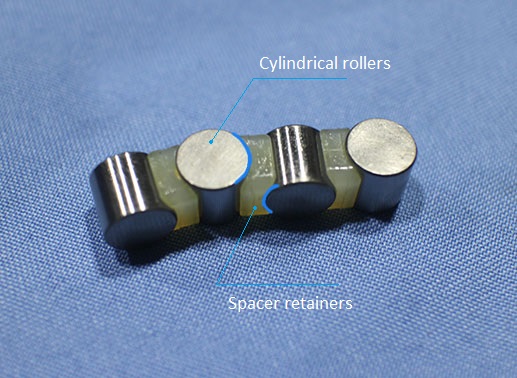

A crossed roller bearing is composed of one inner ring, one outer ring, multiple spacer retainers, cylindrical rollers, and sealings.

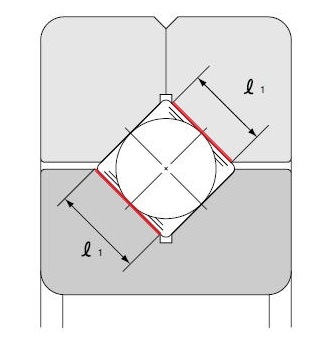

Both inner and outer ring raceway of crossed roller bearing has a "V" shape groove, which is for loading the rollers and separators. This design makes the rollers arranged crosswise, with each roller perpendicular to the adjacent one. So the rollers can take loads from different directions, which enables bearings combined load-carrying capacity.

Spacer retainer and cylindrical rollers - Each roller is separated by a specially designed spacer, which can be in close contact with the rollers and keeps them always in their proper position during rotation. This design can also eliminate friction between rollers, and therefore maintain a stable rotation torque.

Seals - Most cross roller bearing select framework oil seals(skeleton oil seal), which has a better sealing effect than common NBR sealing lips. This type of seals are easy to install, but the cost is higher. And for customized cross roller rings, sealing lips will be selected because the MOQ for sealings is usually very high.

Above is the basic design of cross roller bearings. However, there are various structures of cross roller rings based on their applications. If you are interested, please check cross roller bearing types.