2019 China Bearing Manufacturing Industry – How to Transform and Upgrade?

China's bearing industry has formed a set of independent and complete industrial systems. Regardless of bearing output or bearing sales, China ranks third in the world. The data shows that in 2017, the main business income of enterprises above designated size in China's bearing industry was 178.8 billion yuan, and the output of bearings was 21 billion sets. Bearings with diameter from 0.6 mm to 11 meters can be manufacturered. Although China is already a big bearing producer in the world, it is not a strong bearing production country. The industrial structure, R&D capability, technical level, product quality, efficiency and benefits of China's bearing industry are far from the international advanced level.

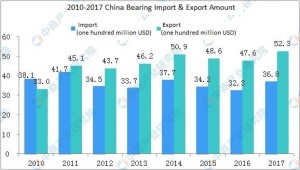

Chinese Bearing Import and Export Situation

From 2006 to 2017, China's bearing export growth was relatively stable, the growth rate was higher than that of imports, and the trade surplus of import and export showed an increasing trend. If we compare the unit price, the price difference between China's import and export bearings is large but has been decreasing year by year. Which reflecting that there is still a certain gap between the technical content of China's bearing industry and the advanced level. At the same time, it reflects the current situation of overcapacity in China's low-end bearings and the shortage of high-end bearing capacity.

Competitive Landscape

China's bearing industry has a significant regional development characteristics. There are mainly five bearing industry clusters: Wafangdian, Luoyang, Yangtze River Delta, Zhedong and Liaocheng.

East China includes private and foreigh-funded enterprises while the Northeast China and Luoyang mainly refer to the state-owned traditional heavy industry bases. With the continuous improvement of marketization in China, private bearing enterprises have become the main force in China's bearing industry. Foreign-owned brand bearing enterprises also occupy an important part of the domestic bearing market. The world's eight largest multinational bearing companies have set up companies & plants in China, and continue to increase investment.

How to Transform and Upgrade China Bearing?

The trend of the current bearing industry is intelligence, high-end, and branding. Below suggestions may be constructive for all operators.

- Improve scientific and technological productivity

- Strengthen professional service levels

- Increase product added value

- Realize the ecological return of profit distribution

Under the current downward pressure of overall economy, BRS Bearing keeps thinking about how to achieve transformation and upgrading, how to seize the times and improve our competitiveness.

The transformation and upgrading of the industry can never be just the upgrading of technology and equipment. It should be an upgrade of the market participants' ideological cognition and thinking mode.

- Introduction of advanced intelligent manufacturing equipment

- International high-end manufacturing talents

- Advanced production management concept

- Innovative business operation model

This will allow the economic structure to be continuously optimized during the upgrade.

The quality and performance of products are the foundation of the enterprise. Brand and service are the foundation of trust, and the differentiated development strategies and business models will bring a broader development space for enterprises.

With the arrival of sharing economy, and in the new trend of "Internet +", the establishment of cooperation and sharing models will open up new development channels for more and more traditional industries! BRS Bearing will focused on the specialization of skills, comprehensive service, and giving customers the largest price space. The new marketing model will also be extremely competitive and win-win, which will lead us into a new era of bearing industry!