How to Select Rolling Bearings Clearance

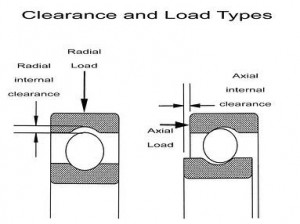

Rolling bearings clearance is an important factor in determining whether a bearing can work properly.

1. The load can be distributed reasonably between the rolling elements.

2. Can limit the axial and radial displacement of the shaft (or casing) to ensure the rotation accuracy of the shaft.

3. Can adjust the bearing stiffness.

4. Allow the bearing to work properly at the required temperature.

5. It can reduce bearing vibration and noise during operation.

Therefore rolling bearings clearance has a great influence on service life, temperature rise, vibration and noise. In order to ensure bearing's normal operation, the appropriate working clearance should be selected according to the working conditions of the machine. Then calculate the original clearance of the bearing based on the working clearance.

Specific factors to consider when confirming a bearing clearance

1. Working conditions (such as load, rotation speed, temperature, etc.)

2. Application requirements (such as friction torque, vibration and noise, rotation accuracy, support stiffness, etc.)

3. When the interference fit is installed, the expansion of the inner ring and the contraction of the outer ring lead to a decrease in the clearance.

4. Under moderate operation, the humidity difference between the inner and outer rings of the bearing and the thermal expansion of the related parts lead to changes in the clearance.

5. Clearance may reduce or increase due to the difference in thermal expansion coefficient of manufacturing material of the shaft and the outer casing.

Experience has shown that the optimum working clearance for ball slewing bearings is approximately zero, while a small amount of working clearance should be maintained for roller bearings. In parts requiring good bearing rigidity (such as machine tool spindles), when there is a negative working clearance, the bearing life is the longest. Crossed roller bearings are open in pre-load, that is with negative clearance.

In a conclusion, when choosing the original clearance, usually take a slightly larger clearance value than zero. In addition to the required preload, single row angular contact ball bearings and tapered roller bearings also retain some working clearance, the former is the negative clearance and the latter is the positive clearance. For the expansion of the shaft during operation, proper axial clearance is required to avoid a large axial load due to the elongation of the shaft and shorten the bearing life.

In general, when selecting a bearing clearance, generally refer to the following principles:

1. For bearings with common applications, the basic group clearance can be selected from the clearance table. In this case, the lower limit of the effective clearance of the bearing is approximately near the maximum service life of the bearing.

2. When it is required to prevent axial turbulence or vibration of the bearing, a clearance smaller than the basic group can be selected to improve the positioning accuracy, rotation accuracy and running smoothness.

3. A largar clearance is suggested in the following case: The load is large, the inner and outer rings are statically fitted at the same time, or the temperature difference between the inner and outer rings is particularly large during operation.

4. When the fit is very tight and the temperature rise is very large, users should consider choosing a larger clearance.