Tips for Selecting A Crossed Roller Bearing

As a professional crossed roller bearing manufacturer, RIGBRS Bearing reminds customers to pay attention to a few tips when selecting a crossed roller bearing.

Since the rollers of crossed roller bearing are alternately crossed at right angles to each other on the raceway, so only one set of cross roller bearing can bear the load in all directions. Compared with the conventional bearings, its rigidity increases by 3 to 4 times. If the inner ring or outer ring of the cross roller bearing is split type, the bearing clearance can be adjusted. Even if preload is applied on the cross roller ring, high-precision rotation can be achieved. These are the reasons why crossed roller bearings become more and more popular.

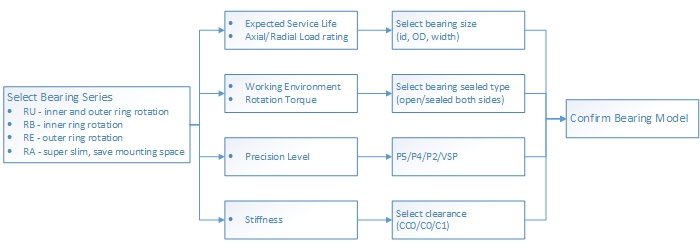

Tips for selecting a crossed roller bearing

The diagram above illustrates the overall idea of choosing a crossed roller bearing. However, there are a few points that need to be paid attention to during selection.

Be clear of your requirements on the crossed roller bearing

When designing new spindles, before selecting a crossed roller bearing, the first thing you need to do is to consider the spindle performance parameters. Roughly determine the most critical performance, and then proceed to further design. (Parameters including spindle speed, spindle accuracy, spindle stiffness, spindle life, spindle heating, and spindle reliability) For example, if the spindle requires the bearings to have high rigidity, then users shall consider the crossed roller bearing with an integrated structure. Such as RU type or CRBH type.

The installation space

The shaft diameter, that is, the inner diameter of the bearing, is generally determined first. Crossed roller bearings with mounting holes can be fixed to the mechanisms directly by bolts without the help of bearing housings or plate. But if it is a thin-section cross-roller bearing such as the RB/RE/CRBH type, a fixing flange or bearing housing will be necessary. Therefore the installation space required by the bearing will be different.

The rotation speed

The limit speed of bearing is usually marked in the bearing datasheet. The cross roller bearing's limit speed is determined by many factors. Such as the bearing type, bearing size, cage type, accuracy grade, load condition, and lubrication method. Therefore, these factors must be considered when selecting a bearing.

The Load rating, load direction and load type

In addition to the magnitude of the load, users should also consider whether there is an only radial load or axial load? Is it a one-way or two-way load? Is there a vibration or shock load? After considering these factors, choose the most suitable cross roller bearing type.

Rigidity

Elasticity deformation is likely to occur on the contact part between the rolling elements and the raceway when the bearing is under load. "High rigidity" means that the amount of deformation is relatively small. On the machine tools, industrial robots, or measuring equipment, bearings should be with high stiffness while the rigidity of the shaft is increased. The roller bearing's deformation is smaller than the ball bearing, and the cross roller bearing uses cylindrical rollers as the rolling element to ensure bearing's rigidity, besides, bearings with negative clearance have higher rigidity.

The rotation accuracy

Bearing dimensional accuracy and rotation accuracy has corresponding national standards. For example, machine tool spindle bearings require high rotation accuracy, high rotation speed, and low friction. Bearings with P5 accuracy or higher should be used. The cross roller bearing accuracy of RIGBRS Bearing can reach P2 or higher grade. Normally P5 grade can meet the rotation requirements of most precision equipment.