Robot Reducer – RV Reducer and Harmonic Reducer

Reducers are widely applied on robots. Both the 3-axis and the 6-axis robots use AC servo motors and are equipped with brakes. In the early days, before robot reducer is popular, most of the ABB robots used their own gear mechanisms to slow down.

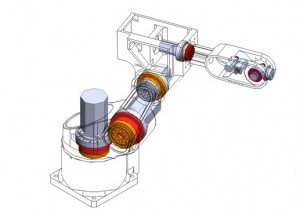

The 1, 2, and 3 axes of the 6-axis industrial robot all use RV reducers and belong to the cycloidal pin wheel structure. 4, 5, 6 axes generally use harmonic reducer. Since the bearings are specially designed, the RV reducer has a short axial dimension. Chinese domestic users mostly use Japanese Teijin and FANUC robot reducer.

What is an RV Reducer?

RV reducer is one of the more common reducers in the worm gear reducer family. It consists of a worm and a worm gear. It has a compact structure and a large transmission ratio. RV reducer has self-locking function under certain conditions, belongs to the most commonly used reducers. Besides, it has low vibration, low noise and low energy consumption.

RV reducer is generally used for low-speed and high-torque transmission equipment. The power from motor or internal combustion engine is transmitted through the gears on the input shaft of the reducer to mesh the large gears on the output shaft to achieve the purpose of deceleration. The ratio of the number of teeth of the large and small gears is the transmission ratio.

The input form of RV reducer is divided into: hole input, shaft input, extended worm shaft type;

The RV reducer output type is divided into: hole output, one-way axis output, and bidirectional axis output.

What is a Harmonic Speed Reducer?

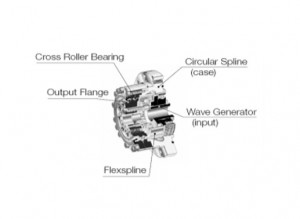

It is mainly composed of four basic components: wave generator, flex spline, circular spline and flexible bearing. The flexible bearing is assembled with wave generator to make the flexible gear produce controllable elastic deformation, and meshes to circular spline to transmit motion and power.

Basic characteristics of harmonic reducer

1. High load carrying capacity. Because the tooth and tooth meshing is surface contact, and the number of meshing teeth (overlap coefficient) is relatively large, so the load per unit area is small, and the bearing capacity is higher than other transmission forms.

2. Large transmission ratio

3. Small size and light weight.

4. High transmission efficiency and long life.

5. The transmission is smooth, no impact, no noise, and high motion accuracy.

6. Because the flexible wheel is subjected to a large alternating load, the requirements for fatigue strength, processing and heat treatment of the flex spline material are high and the process is complicated.

The harmonic reducer was developed in China since the 1960s and 1970s. BRS Bearing started to research can develop bearings for RV reducer and crossed roller bearings for harmonic reducer since 2010. Reducers are widely used in electronics, aerospace, robotics, chemical industry and other industries.