Rolling Mill Bearings – Rolling Bearings for Roll Neck

BRS started to produce bearings for rolling mills since 2005 and gethered extensive experience. We provide suggestions for rolling mill designers and help them to confirm the most suitable roll neck bearings. Infomation regarding dimension, mounting and dismounting, lubrication and maintenance can be found on each rolling mill bearings product page.

Roller neck bearings mainly include cylindrical roller bearings, tapered roller bearings, and spherical roller bearings. The material used for the bearingrings and rolling elements is through hardening rolling bearing steel or case hardening steel.

When selecting the bearing type, the replacement frequency of rolls must be taken into consideration. Because the reworking of the roll bodies is accompanied by removal of the chocks. And for non-separable bearings such as spherical roller bearing, the replacement procedures are very complicated. But a split spherical roller bearing can solve this problem.

In the case of cylindrical roller bearings, the chock can be removed together with the outer ring and roller cage from the inner ring mounted on the neck. Four-row tapered roller bearings or two spherical roller bearings arranged together on a cylindrical neck have a loose fit. So the chocks can be easily removed.

Cylindrical Roller Bearings

This type of bearing is suitable for very high radial loads and high speeds. Cylindrical roller bearings are mainly used with a tight inner ring fit, and its internal structure has different types:

1. Through-drilled rollers and pin-type cages - this type can accomodate the maximum possible number of rollers in the bearing so as to achieve a high loading capacity.

2. Double row cylindrical roller bearings with inner and outer spacers between bearing rings - this type can reduce the stresses caused by any moments. Suited for applications which do not have high requirement on loading capacity, but requires high rotation speed.

3. Four-row cylindrical roller bearing with machined cage - mainly used in fine-section and wire mills. They have machined brass or steel cages, can support high loads and suited for high rolling speeds.

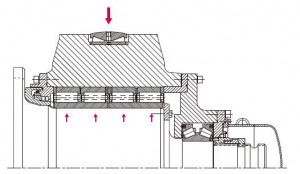

Axial Bearings

Axial tapered roller bearings, double row tapered roller bearings or axial spherical roller bearings are used on the roll neck for high axial forces and moderate speeds. Mainly used in blooming mills, hot strip mills, and heavy plate mills, where considerable axial forces occur in combination with low to moderate speeds.

However, if the rolling speed is very high, it's no longer suitable to use above bearings. Angular contact ball bearings or deep groove ball bearings will be applied. But they are only required to support axial forces.

Single direction axial tapered roller bearings are ofter mounted between the pressure spindle and the upper chock. These bearings can reduce the screw-down forces due to their low friction.

Tapered Roller Bearings

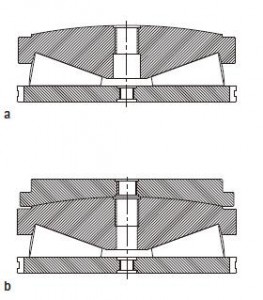

Due to the inclined postion of the rollers, tapered roller bearings can support radial and axial loads at the same time. Four row and double row tapered roller bearings are used in rolling mills. Since they have a loose fit on the neck, the inner ring will inevitably creep on the neck.

So the neck will undergo heating and wear. But can be restricted by good lubrication. The inner rings of roll neck bearing mush have a tight fit, so tapered roller bearings with a tapered bore are normally selected.

Spherical Roller Bearings

When the speed is low and the demands on axial guidance accuracy are not very high, spherical roller bearings can be used. The common type for rolling mills are dimension series 240 and 241. Due to its self-alignment characteristic, the chock can be supported easily in the roll stand. Any deflection of the roll neck and inaccuracy of the roll stand will be compensated by the bearing.