Slewing Bearing Environment and Working Temperature

Slewing bearings are often used in mechanical equipment and can withstand axial force, radial force, and tilting moment. When purchasing and using a slewing bearing, it is also necessary to have a certain understanding of its working environment and adaptation temperature.

Heat treatment of slewing ring and gear

The raceway of the slewing bearing is treated by induction hardening on the surface, and the quenching hardness is ensured at HRC58~62, which can reach a sufficient depth of the hardened layer.

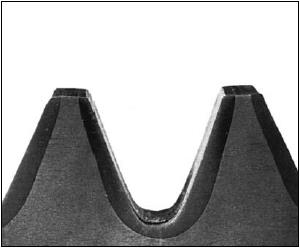

Because of the need to transmit force, there are sometimes teeth on one of the slewing rings. The heat treatment condition of the gear is generally normalized or quenched and tempered. The tooth surface can also be quenched according to user requirements. The quenching hardness is HRC50-60, and sufficient depth can be ensured. According to different applications, gear quenching can be divided into spin hardening and individual tooth induction quenching. Single tooth induction hardening can be divided into tooth flank hardening and tooth contour hardening.

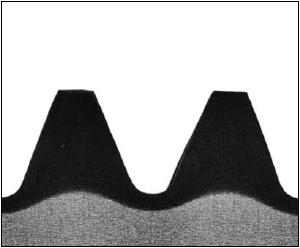

gear spin hardening

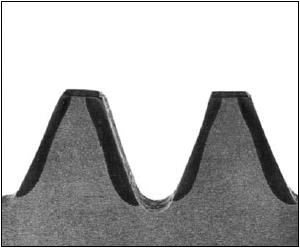

gear teeth flank hardening

gear tooth contour hardening

Slewing bearing installation environment

In order to ensure the friction effect between the bearings, and realize the stability of the bearing operation, a certain amount of lubricating products must be added to the slewing ring during operation. The equipment must be inspected before operating to prevent bearing failure.

The installation surface should be smooth and clean. All unnecessary substances such as paint residue, solder beads, burrs, etc. should be removed. When cleaning, be careful not to let the solvent penetrate into the slewing ring during cleaning, and do not use solvents that damage the sealing material. The mounting surface should be dry and free of lubricant before assembly. Measures should be taken to protect workers and the environment.

In order to avoid local overload of the slewing ring caused by unevenness of the installation surface or deformation of the support, the circumferential flatness error can only have one wave ups and downs within any range of 180 degrees, and the change needs to be gentle. Check "How to install and maintain slewing bearing?" for more detailed info.

Slewing bearing working environment

If the slewing bearing is applied in a very harsh environment, such as smoke or dust, sand, concrete, pulverized coal, and other fine particles in a natural environment, a unique sealing ring, and suitable oil passage should be adopted. Therefore, in order to ensure the performance of your slewing bearings, daily maintenance is very necessary.

Slewing bearings working temperature

The slewing ring can work normally from -20℃~+80℃. Lower or higher temperatures are possible but require special design or material, please contact BRS engineer for details. For example, the slewing bearing used under extreme standards, such as corrosion resistance, salt and alkali resistance, etc., the bearing material must be unique corrosion-resistant raw materials. However, during actual operation, slewing bearing may often encounter an overheating problem, check Reasons for slewing bearing overheating, and learn how to extend your slewing rings service life.