Yaw Bearings and Pitch Bearings Mounting and Maintenance

Yaw bearings and pitch bearings mounting are similar to the installation method of slewing ring bearing products. But there are some small details that need to be paid attention to, so users can extend your wind turbine bearings service life.

Yaw Bearings and Pitch Bearings Mounting

1. Mating Surface

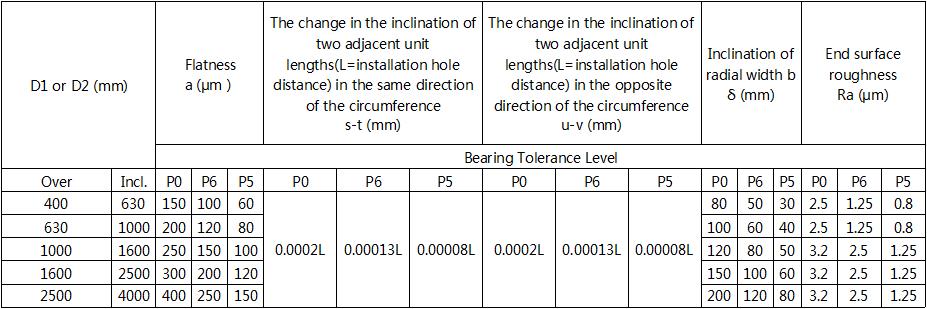

Before installing and using each set of bearings, the matching surface should be inspected. In addition to the sufficient rigidity of the parts supporting the bearing, the mating surface should be machined to remove surface debris and burrs. The technical requirements for the supporting part's mating surface shall meet the requirements of the following table.

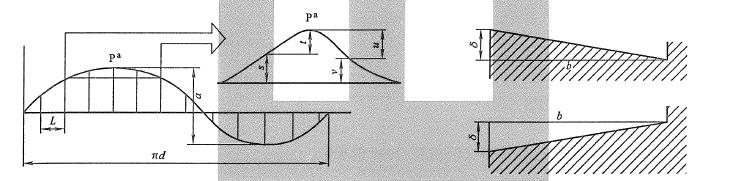

The flatness of the mating surface and the inclination in the radial width are shown in the figure below.

2. Installation Method

The yaw and pitch turntable bearings produced by BRS have a hardness gap on the rings. The user should place the hardness gap in the non-load area (the load plug is located at the soft spot) during installation. When installing, position the slewing bearing radially first, then tighten the mounting bolts crosswise, and check the rotation of the slewing bearing. In order to ensure smooth rotation of the slewing bearing, the gears should be checked for meshing before the bolts are completely tightened. The pre-tightening force when tightening the bolts should be 70% of the yield limit of the bolt material. When installing the bolts, quenched and tempered flat washers should be equipped.

Maintenance of Yaw Bearing and Pitch Turntable Bearings

After the yaw and variable pitch slewing bearings are installed, they should be filled with grease. Rotate the yaw bearings or pitch bearings while greasing to make the grease evenly distributed. The grease shall generally fill up the inner space of the bearing. After installation, pitch bearings should be check and refill grease after 100h continuous operation. Thereafter refill the grease every 500h continuous operation. For bearings that work in a high-temperature environment, the cycle should be appropriately shorter. When the machine stops running for a long time, it should also be filled with sufficient grease too.

Related Yaw Bearings, Pitch Bearings, and Blade Bearings Products

Four-point contact ball slewing bearing with no gear. (010 series)