Slewing Bearing Material

The property and quality of raw material have a great influence on bearings' performance and service life. BRS only use materials from qualified supplier, and we will conduct strict inspection on the forging parts, including ultra sonic inspection, hardness inspection and metallographical examination.

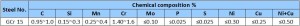

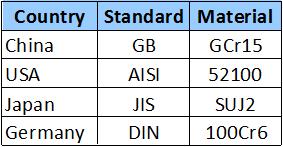

GCr15 Steel

For precision slewing bearing material, such as crossed roller bearing, harmonic reducer bearing, BRS use GCr15 bearing steel as raw material. As a representative steel of high carbon chromium bearing steel, GCr15 is with less alloy content and has a good overall performance. After quenching and low temperature tempering, GCr15 bearing steel will achieve high hardness, uniform structure, good wear resistance and high contact fatigue performance. It's usually used to manufacture precision bearing rings and rolling elements.

The normal quenching temperature of GCr15 steel is 830-860 °C.

The tempering temperature of GCr15 steel is generally 160-180 °C.

This steel has good hot workability, medium cold workability, and general cutting performance. Besides, GCr15 weldability is poor and has temper brittleness.

As a bearing steel, GCr15 has high requirements for smelting quality, and it is necessary to strictly control the content and distribution of sulfur, phosphorus and non-metallic inclusions, which will have a great influence on the service life of bearing steel.

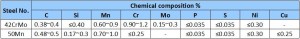

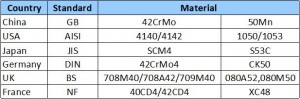

50Mn and 42CrMo Steel

For slewing bearing material, BRS usually use 50Mn or 42CrMo as the raw material.

50Mn is a high quality carbon structural steel. It has high strength, elasticity and hardness, often used after quenching and tempering. The welding performance of 50Mn is poor, and it has a tendency to overheat sensitivity and temper brittleness. 50Mn is usually used to manufacture components which has high requirement on wear resistance and loading capacity, such as gears and gear shafts.

42CrMo material is a kind of alloy steel, which is very suitable for forging processing. It has high strength, high hardenability and good toughness. The deformation of 42CrMo during quenching is small, and it has high creep strength and long-lasting strength at high temperatures. Compared to 50Mn, 42CrMo has better fatigue endurance, but its cost is higher.