Crossed Roller Bearings for Welding Robots

Bearings for welding robots must be with high rotational accuracy and high stiffness. Because robotic welders need to be very accurate during operation and not to lose accuracy even after long time of repeatable movement in welding process.

Bearings Applied on Welding Robots

- For the base of the welding robots arm, high stiffness crossed roller bearings with larger size are often applied. Such as RU124, RU148, RU178, RU228 and RU297 cross roller rings.

| Model | id(mm) | OD(mm) | Width(mm) |

| RU42 | 20 | 70 | 12 |

| RU66 | 35 | 95 | 15 |

| RU85 | 55 | 120 | 15 |

| RU124G | 80 | 165 | 22 |

| RU124X | 80 | 165 | 22 |

| RU148G | 90 | 210 | 25 |

| RU148X | 90 | 210 | 25 |

| RU178G | 115 | 240 | 28 |

| RU178X | 115 | 240 | 28 |

| RU228G | 160 | 295 | 35 |

| RU228X | 160 | 295 | 35 |

| RU297G | 210 | 380 | 40 |

| RU297X | 210 | 380 | 40 |

| RU445G | 350 | 540 | 45 |

| RU445X | 350 | 540 | 45 |

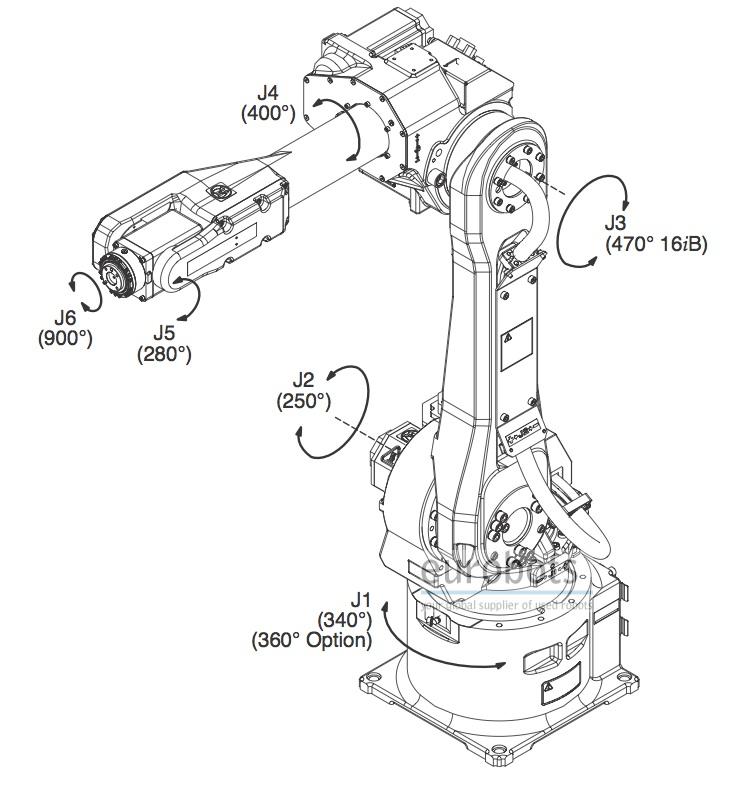

- For the 2nd axis to 6th axis, crossed roller bearings that specially designed for CSF/CSG and SHF/SHG harmonic reducers are ofter selected. BRS produce full size range of harmonic drive units bearing from 14 to 65, custom design also available.

About Welding Robots

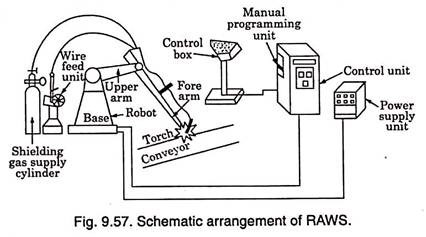

A welding robot holds a welding torch and manipulates this around a work piece in a similar way as a human welder. Traditional robots such as 6 axis industrial robots are still extensively used for arc welding, and there are also dedicated arc welding robots too.

Application of Welding Robots

Welding robots are not only used in the automobile manufacturing industry, but also have been widely used in engineering machinery, steel structures, nuclear power and wind power, aerospace, marine and marine engineering, rail transportation, national defense, industrial appliances, civilian hardware and other industries.

Development of Welding Robots

Welding plays a pivotal role in industrial production. In recent years, with the continuous development of science and technology, the demand for high-quality products has greatly increased. At the same time, higher requirements have been placed on welding technology.

The traditional manual welding technology can no longer meet the needs of today's product production in terms of quality and efficiency, so the automation of welding has gradually become more and more important to the world.

As the most important application segment of industrial robots, welding robots have developed very rapidly and have been widely used in various fields of industrial manufacturing, accounting for about 40% of the entire industrial robot applications. Welding robots have become a symbol of welding automation.

Chinese Bearings for Welding Robots

China's industrial robot research and development is relatively late, so overall, China has been lagging behind Europe and the United States, Japan and other countries. Moreover, in the early days of the development of robots in China, many components such as bearings, servo motors and reducers need to be imported. Therefore, the cost of finished products has been increased, which has restricted the development of China.

However, under the current high-tech economic situation, more and more Chinese suppliers began to focus on R&D and innovation, and can produce most components including welding beams. We believe the international status of China's manufacturing industry will be improved gradually.