-

Part NO.

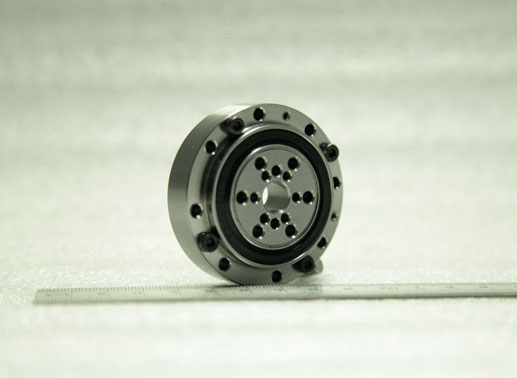

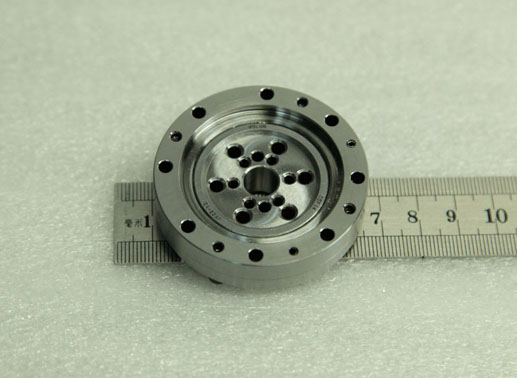

Open type:CSF14-XRB

-

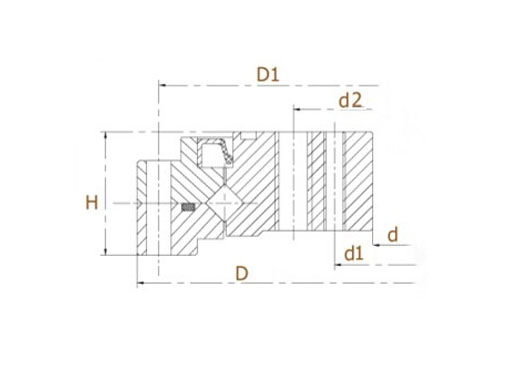

Dimension

d:9mm

D:55mm

H:16.5mm

-

Mounting

d1:14.5mm

d2:23mm

D1:49mm

-

Basic Load Ratings

-

Equivalent Model

- Features

- Mounting

CSF-14 harmonic reducer bearing specifications:

Type of guide Roller Space retainer Yes Material GCr15 Standard lubrication method Grease lubrication Oil hole No Sealing Framework oil seal on one side Radial clearance -0.01 ~ 0 Rotation accuracy P5 Working temperature -20℃ ~ 80℃ Other CSF|CSG harmonic reducer bearing models.

CSF14-XRB output bearing features:

1. Integrated inner ring with split outer ring.

2. Sustain radial, axial and moment loads at the same time.

3. High stiffness, high rotation accuracy and high loading capacity.

4. Compact structure with mounting holes on inner and outer ring, easy to install and save space.

5. Speically designed for CSF-14 and CSG-14 harmonic speed reducer drive units, customized size and structure also available.

6. Full complement rollers type available.

Applications

-Industrial robot / intelligent robot

-Multi-axis robotic arm for home or industrial use

-Precision processing machinery

-Wind power fan blade control

-Aerospace and marine scienceFAQ

1. I’m designing a prototype, can you produce according to my design?

Yes, BRS can produce custom design harmonic reducer bearing based on users requirements, but there will be a MOQ.2. Do you offer the whole harmonic gear system?

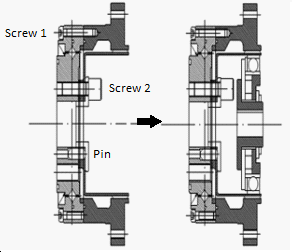

No, BRS only produce the crossed roller bearings for harmonic drive units.CSF-14 harmonic reducer bearing mounting instructions:

1. Before installation, please clean bearing bracket, shaft, or other components,

make sure there is no burrs or rough edge.

2. Install the locating pin to output bearing.

3. Install the Screw 1, then install the Screw 2.

4. Install the wave generator and related components.